Recently, the New York City Department of Environmental Protection has been using their Facebook page to post old black-and-white photos, taken during the construction of the city's massive water system in the last century.

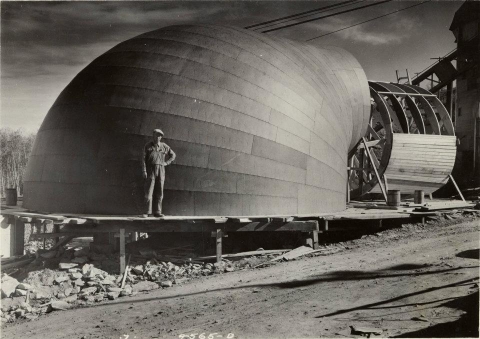

Above: A September, 1941 photo showing how the tunnel connecting the Rondout Reservoir to the underground Delaware Aqueduct was painstakingly built with wooden molds and concrete. The DEP's caption:

Wooden forms were used in the construction of the Delaware Aqueduct to shape the concrete lining of the tunnel as it was poured. This wooden form was used to mold the gooseneck shape that connected the Rondout Reservoir effluent chamber (water leaving the reservoir), to the connecting tunnel which led to the first shaft of the Delaware Aqueduct. September 1941. (Image DEP Archives hdq.d.5895)

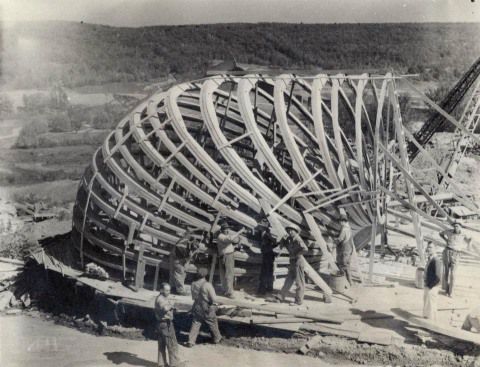

Below: A later photo of the same structure, taken in October of 1941:

After it had been constructed, the gooseneck form was let down in sections, rebuilt in the tunnel and then raised into position. October 9, 1941. (Image DEP Archives hdq.d.4565)

The Delaware Aqueduct, completed in 1945, is now leaking millions of gallons of water a day underground, a situation that has led to chronic flooding of homes in Wawarsing. The DEP is working on repairing the tunnel, and also planning to build a bypass tunnel to divert water around a badly leaking section, a project slated to be finished in 2019.

Repairing the aqueduct is hardly less monumental a task than building it in the first place, as a 2008 New York Times story about ongoing aqueduct repairs illustrated vividly. Reporter Ken Belson describes the process of repairing a valve at the bottom of a 700-foot shaft:

For this, the city has enlisted six deep-sea divers who are living for more than a month in a sealed 24-foot tubular pressurized tank complete with showers, a television and a Nerf basketball hoop, breathing air that is 97.5 percent helium and 2.5 percent oxygen, so their high-pitched squeals are all but unintelligible. They leave the tank only to transfer to a diving bell that is lowered 70 stories into the earth, where they work 12-hour shifts, with each man taking a four-hour turn hacking away at concrete to expose the valve.

For more photos from the building of the reservoirs, check out the DEP's Facebook page, or search the archive of historical photos on their website.